“I just want to say one word to you. Just one word: plastics!” Mr. McGuire to Benjamin Braddock in The Graduate, 1967.

Well, in reality Mr. McGuire could have said, “I just want to say one word to you: polytetrafluoroethylene!” While that wouldn’t make for good cinema, it could have made you really rich! The material is a plastic with the abbreviation PTFE, but most people know it under the more common name, Teflon!

Wilbert “Bill” Gore was a chemical engineer and innovator who worked for Dupont. Dupont had identified and trademarked Teflon in 1938. The primary application had been as a non-stick surface. But in 1958 Bill Gore saw enough promise in additional applications for Teflon that he and his wife, Vieve, started their own company, W. L. Gore & Associates. One of his first successful commercial applications was as a wrapping for electrical cables. The material was flexible and weather-proof allowing usages that other cabling couldn’t match. One of the customers for the cables was IBM who used them extensively in their highly successful S/360 computer systems.

Robert “Bob” Gore was one of Bill and Vieve Gore’s five children. He followed in his father’s footsteps majoring in chemical engineering and also inherited his father’s innovative spirit. Bob’s idea for using a different form of PTFE to wrap the cables led to the success of their early product. During his college years he actually worked for an aerospace company other than his father’s since they would pay him more!

After obtaining his PhD in 1963, Bob did go to work for his father. One of the problems with PTFE was that it couldn’t be stretched into larger sheets without breaking. Bob took on this problem at its most basic level. By experimenting with heated rods of PTFE, he tried to slowly stretch the material, but no matter how slowly he stretched, the rod would break after only reaching an additional 50% of its length. After a particularly frustrating set of experiments, Bob took one of the rods and quickly yanked it. The rod stretched, but didn’t break! Expanded PTFE (ePTFE) was born, but we know it by another name Gore-Tex!

Glen Findholt correctly answered last week’s trivia question identifying Bob Gore as the inventor of Gore-Tex. Glen says:

“My first ever Gore-Tex garment was a North Face “Extreme Gear” shell which I was quite proud of. I wore it constantly with little regard for its care and feeding. I should have figured out that a membrane is only functional when it’s clean and by the time I got around to using it in wet weather the membrane was quite plugged with dirt and I got just as wet as had I worn a garbage bag!”

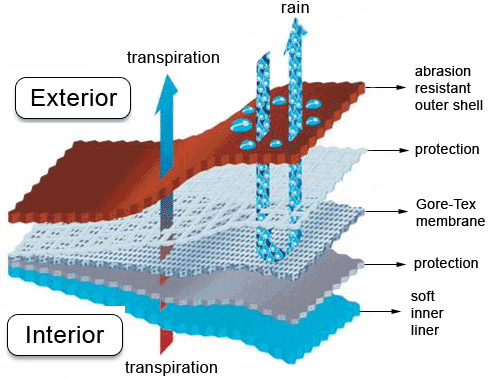

Glen’s comment brings us to how Gore-Tex works. The Gore-Tex layer is porous, but the pores are small enough that water won’t pass through, but air can. In other words the layer is waterproof, but breathable! When Glen didn’t clean his garment he defeated a lot of that characteristic.

Gore-Tex was patented in 1969 and the first outdoor gear to employ it appeared in the mid-1970s. In some respects we are fortunate that the Gore family were outdoor people so saw that ePTFE had an application there.

Glen Findholt has been a long-time instructor at Smuggs and shared a story of when the Smuggs ski school got Gore-Tex uniforms while the Stowe ski school went to “Entrant” which was another company’s attempt to improve on Gore-Tex. The attempt to improve failed so Glen says, “the joke around both Smuggs’ and Stowe ski schools was that Entrant was the French word for ‘sponge’!”

The history of skiwear is driven by the need to keep participants warm and dry. Early efforts emphasized warm, but you could get wet from the outside in. Later as nylon was developed into waterproof materials that didn’t breathe, you got wet from the inside out! Gore-Tex led the way to materials that are really waterproof and breathable.

So going back to the way I started this column, for the Gore family and the company they started the one word was “Teflon!”

Leave a Reply