At the Killington World Cup I volunteered at the Vermont Ski and Snowboard Museum’s tent in the Vendor Village. We had a small selection of old skis and old ski boots. The ski boots drew more attention than the skis! The old lace up leather ski boots turned out to be a real attraction.

“Leather ski boot” is an oxymoron – a combination of opposites. Ski boots need to be laterally rigid for proper edge control and the forward flex should be stiff so that forward force is transmitted to the front, turning portion of the ski. “Rigid” and “stiff” are not words typically associated with leather. Leather becomes soft and pliable with repeated use. In other words the attributes we need in a ski boot degrade over time with leather. So let’s look at the phases in a leather ski boot’s life.

- The Fitting Phase

- The Break-in Phase

- The Comfort Phase

- The Adjustment Phase

Wait a minute. Aren’t those the phases for any ski boot? Well, yes, but today the Comfort Phase and the Adjustment Phase can be measured in years while for leather boots they were measured in days!

The Fitting Phase: A leather ski boot needed to be uncomfortably tight in the shop, some would say painfully tight. If the boot was comfortable in the shop, then it would be too loose when broken-in.

The Break-in Phase: The break-in period for a pair of leather boots varied and each person developed his/her own approach. Some wore their boots around the house for gradually increasing intervals. Some filled their boots with hot water, let them sit for a half hour, then emptied them and wore them around for a half hour. Others like me used the early ski season. It took me about 7-10 ski days to break in my boots. The break-in was a painful period!

The Comfort Phase: Once broken-in, the boot could be skied with minimal or no pain. On warm days you could ski all day in your boots! Cold days still required warming visits to the lodge since leather got its support from tightness which leads to cold feet! For leather boots this phase lasted 2 days – well, maybe longer if you had some really good boots.

The Adjustment Phase: As leather boots softened, adjustments were required to achieve support. During the ski day you would have to re-lace your boots to make them tighter or re-wrap your long thong (Don’t ask!). The length of this phase depended as much on your budget as it did the boot condition! By the way, if you went directly from the Break-in Phase to the Adjustment phase, then your boots hadn’t really fit you in the first place!

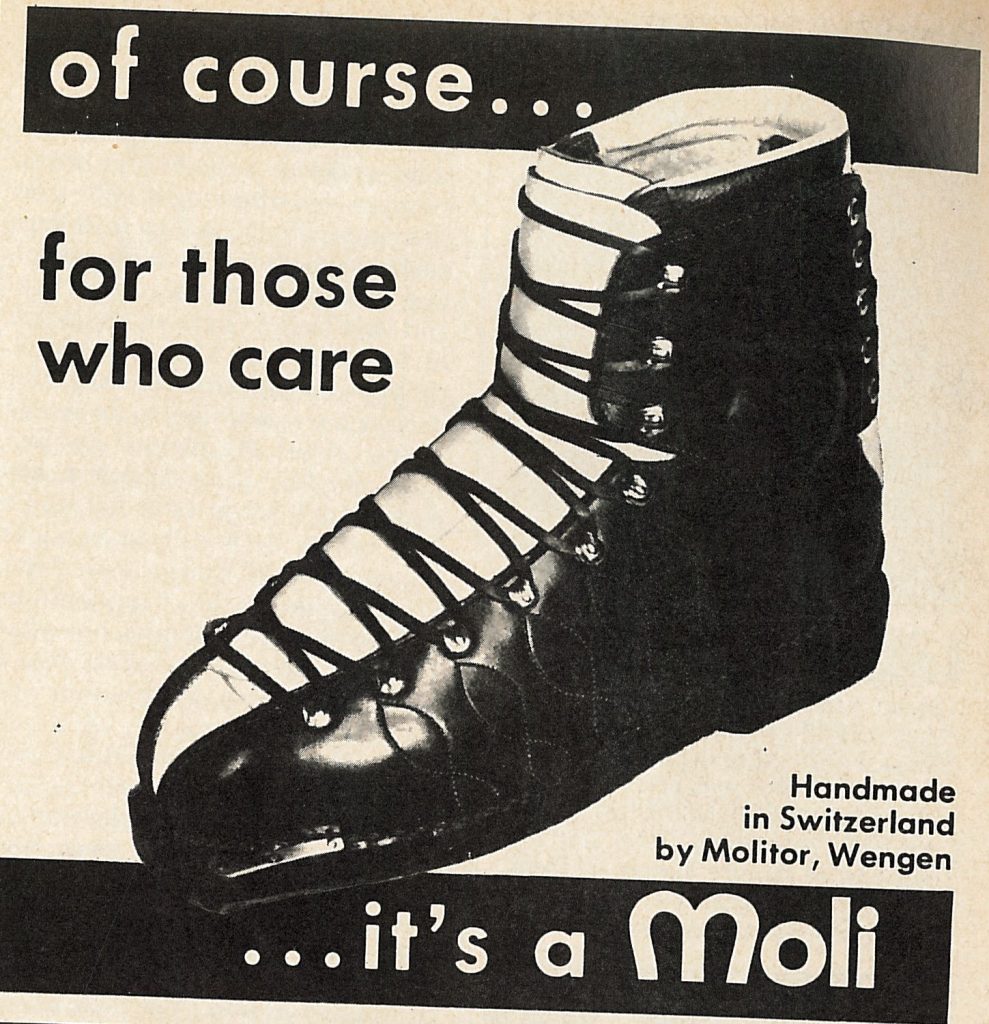

The dream leather boot for my circle of friends was the Molitor or Moli (pronounced Molly) for short. Karl “Moli” Molitor was a successful Swiss ski racer from Wengen, Switzerland. He designed the boots based on what he felt skiers needed and had them hand-made to his specifications. The boots were known for their performance without involving the pain many of us associated with leather boots.

Molitor boots were more expensive than other boots so some of us could only envy those who could afford them. In the 1950’s Molis could cost $100 while other brands were under $50.

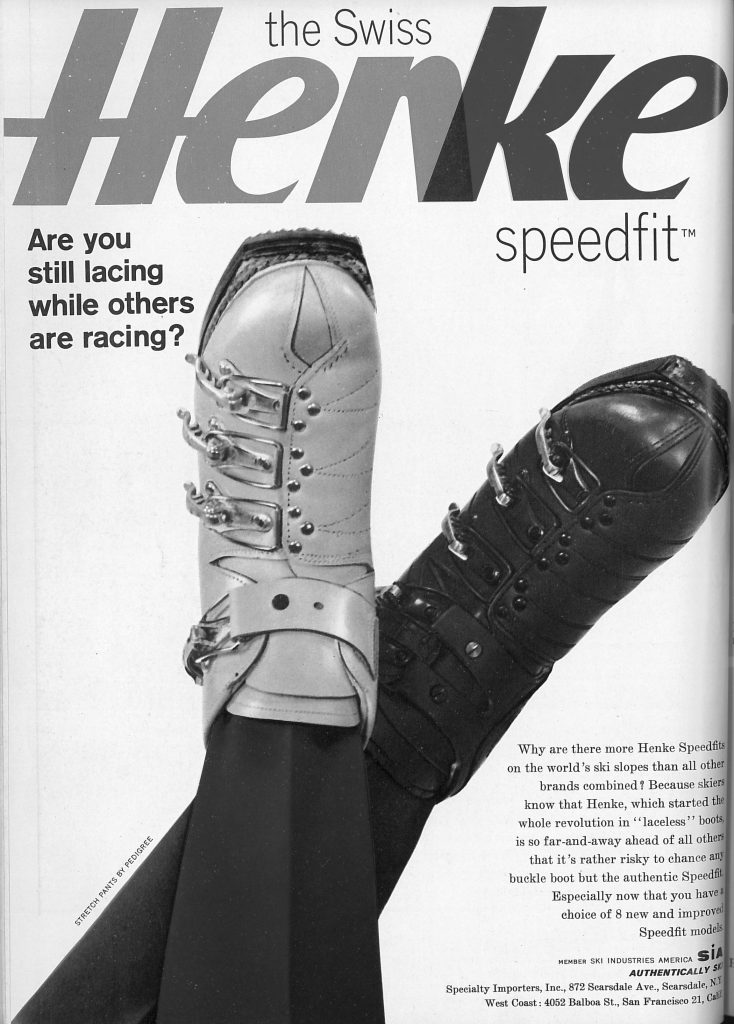

Henke, a Swiss/German company, introduced the first buckle leather ski boot in 1955 and used the “Are you still lacing while others are racing?” slogan to promote its Speed-Fit boot. By the early 1960’s Henke ski boots were the best-selling ski boot in the United States. Henke is another example of a once successful, skiing-related company that is no longer with us.

Buckle leather ski boots were faster to get on-and-off plus you could loosen the buckles on the lift-ride and delay the cold feet syndrome for a couple more runs. Buckles also provided a mechanical advantage so during the Adjustment phase of a leather boot’s life you could tighten them more easily than with laces. Choose your own pain level so-to-speak! This could actually shorten a boot’s life since tightening the buckles could stretch the leather and hasten the breakdown of the boot. The answer to the leather ski boot problem was plastic ski boots, of course. So next week we’ll talk about some of the early entries into that technology.

January 11, 2024 at 1:50 pm

I remember my first “beginner’s ski package” from our local ski shop in 1969. Fischer Quick Super skis, Cubco bindings, and a pair of red leather Heierling buckle boots. My dad was unconvinced that I might learn the sport more readily on the Rossignol Strato’s and Lange boots (“if you want anything better than the basic package – you can pay for it”). Actually the Heierlings held up well over a few seasons – and were comfortable and supportive. More so than the plastic Cabers that I had next. Knowing the lifespan of early thermoplastics I ask if you had your choice of skiing in 60 year old leather boots or 40 year old plastic ones – which would you feel safer in? (asked by someone who has seen a few pairs crackle into a thousand pieces).